Description

The TC4423A/4424A/4425A are a family of dual, 3A-output MOSFET Drivers, which are high-current buffer/drivers capable of driving large MOSFET transistors and Insulated Gate Bipolar Transistors (IGBT).The TC4423A/4424A/4425A have matched leading and falling-edge propagation delay times and have very low cross-conduction currents that help minimize the overall power dissipation of these devices. Infineon is the market leader in highly efficient solutions for power generation, power supply and power consumption. The latest generation of Infineon's MOSFET transistors were designed to ensure market leading performance, improve efficiency and to achieve better thermals in.

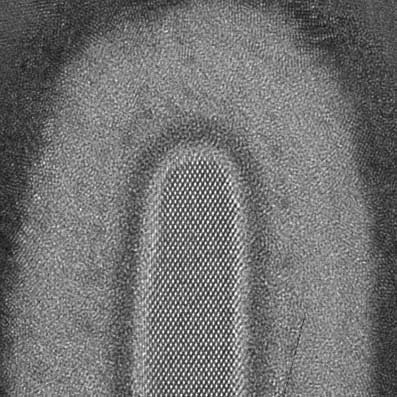

This MOSFET module uses two parallel N-Channel logic compatible MOSFETS with low Rds(on) for high current low-side switching applications.

PACKAGE INCLUDES:

- High-Power Dual MOSFET Switch Module

KEY FEATURES OF HIGH-POWER DUAL MOSFET SWITCH MODULE:

- One switching output

- Parallel MOSFETS provide low Rds(on) resistance

- 3.3 – 20V input control voltage

- 5 – 36V output switching voltage

- 15A continuous current handling capability (See notes below)

- 3.3 and 5V logic compatible (See notes below)

The modules utilizes the AOD4184 N-channel MOSFET that has a low Rds(on) resistance of 8.5mΩ typical when driven with a 4.5V logic signal. The module puts two of these devices in parallel to reduce the Rds(on) to 4.25mΩ and double the power handling capability without resorting to bulky heat sinks.

These modules are most commonly driven using 5V logical which supports about 15A of continuous current. If driven with PWM, the maximum peak current can be greater up to 40A or more.

While the modules are technically 3.3V logic compatible, they must be derated for safe operation. Since 3.3V logic may only swing to 3V when a logic HIGH, current may need to be limited to < 10A to avoid excessive heating. See our test results below for more info.

Note that the module does not have a flyback diode on the board. If using the module with inductive loads, an external flyback diode should be used to avoid possible damage.

Module Connections

The module requires 3 connections. A logic signal to turn the MOSFETS on/off; a DC power supply to power the device (load) being controlled and finally the load itself. While it may seem a bit complicated, just follow the drawing shown here.

The connector location J1 is for making the logic signal connection. It has two holes on 0.2″ centers which support a 2 position screw terminal as well as four holes on 0.1″ centers that can support a male or female header. The pins are labeled TRIG/PWM on the back of the board for the signal and GND for the signal ground.

The DC Load Power Supply is connected to the screw terminals marked VIN+ / VIN- on the back of the module. The positive lead of the power source connects to VIN+ and the ground connection is hooked up to VIN-

The Load which is being driven is connected to the screw terminals marked OUT+/OUT- on the back of the module. The positive lead connects to OUT+ and the negative lead connects to OUT-

The signal ground and VIN- ground connections are connected together on the module.

J1 (Logic Signal Input)

- TRIG/PWM = Signal input (active HIGH).

- GND = Signal ground

1 x 2 Screw Terminal (Load Power Supply)

- VIN+ = Connect to power supply (5-36V) being used to power the load

- GND = Connect to power supply ground

1 x 2 Screw Terminal (Load)

- DC+ = Connect to positive lead of load (motor, LEDs, fan, etc)

- DC- = Connect to negative lead of load

N Channel Dual Gate Mosfet

The module bag usually has a male header strip included, but if you want a screw terminal connection for your control lines, these will get the job done. Vectoraster.

OUR EVALUATION RESULTS:

These modules work well for basic ON/OFF operation such as for driving a solenoid or PWM control such as for dimming an array of LEDs and can handle a surprising amount of power given the small size. It is also possible to parallel these modules to further increase the power handling capability.

One important point to take note of is that if an inductive load is being controlled, an external flyback diode should be used to prevent possible damage when the load is switched off.

The chart to the right from the datasheet shows the effect of the drive (Gate) voltage on the maximum potential current through the individual MOSFET devices.

The chart below shows some example temperature measurements of the MOSFETs with a load varying from 5A to 25A @ 12V. The logic drive signal varies from 3.0, 3.3, 4.5 and 10V with a 100% duty cycle (always on), 50% duty cycle or 25% duty cycle. The measurements are being taken with no airflow over the module and an ambient temperature of 22C.

4.5V is the typical drive voltage for 5V logic. By the same token 3V is the typical drive voltage for 3.3V logic. 10V is where the device achieves its minimum Rds(on) and therefore has the lowest possible power dissipation. Our testing on the low end using 3V and 3.3V was better than expected, but devices can vary so use caution if using a drive signal under 4.5V.

In general, you should keep the MOSFETs under about 100°C to keep them happy. For long-term use, 80°C would be a better target.

| Load Amps | 3V 100% | 3V 50% | 3.3V 100% | 3.3V 50% | 3.3V 25% | 4.5V 100% | 4.5V 50% | 4.5V 25% | 10V 100% |

| 5A | 38°C | 34°C | |||||||

| 10A | 82°C | 57°C | 69°C | 49°C | 42°C | 58°C | 52°C | ||

| 15A | X | 96°C | 130+ | 82°C | 54°C | 101°C | 66°C | 83°C | |

| 20A | X | X | X | X | 78°C | 140°C+ | 95°C | 131°C | |

| 25A | X | X | X | X | 100°C | X | 125°C | 76°C | X |

BEFORE THEY ARE SHIPPED, THESE MODULES ARE:

- Sample tested per incoming shipment

Notes:

- The bag usually has a 1×4 male header strip included.

Technical Specifications

Dual Gate Mosfet

The module requires 3 connections. A logic signal to turn the MOSFETS on/off; a DC power supply to power the device (load) being controlled and finally the load itself. While it may seem a bit complicated, just follow the drawing shown here.

The connector location J1 is for making the logic signal connection. It has two holes on 0.2″ centers which support a 2 position screw terminal as well as four holes on 0.1″ centers that can support a male or female header. The pins are labeled TRIG/PWM on the back of the board for the signal and GND for the signal ground.

The DC Load Power Supply is connected to the screw terminals marked VIN+ / VIN- on the back of the module. The positive lead of the power source connects to VIN+ and the ground connection is hooked up to VIN-

The Load which is being driven is connected to the screw terminals marked OUT+/OUT- on the back of the module. The positive lead connects to OUT+ and the negative lead connects to OUT-

The signal ground and VIN- ground connections are connected together on the module.

J1 (Logic Signal Input)

- TRIG/PWM = Signal input (active HIGH).

- GND = Signal ground

1 x 2 Screw Terminal (Load Power Supply)

- VIN+ = Connect to power supply (5-36V) being used to power the load

- GND = Connect to power supply ground

1 x 2 Screw Terminal (Load)

- DC+ = Connect to positive lead of load (motor, LEDs, fan, etc)

- DC- = Connect to negative lead of load

N Channel Dual Gate Mosfet

The module bag usually has a male header strip included, but if you want a screw terminal connection for your control lines, these will get the job done. Vectoraster.

OUR EVALUATION RESULTS:

These modules work well for basic ON/OFF operation such as for driving a solenoid or PWM control such as for dimming an array of LEDs and can handle a surprising amount of power given the small size. It is also possible to parallel these modules to further increase the power handling capability.

One important point to take note of is that if an inductive load is being controlled, an external flyback diode should be used to prevent possible damage when the load is switched off.

The chart to the right from the datasheet shows the effect of the drive (Gate) voltage on the maximum potential current through the individual MOSFET devices.

The chart below shows some example temperature measurements of the MOSFETs with a load varying from 5A to 25A @ 12V. The logic drive signal varies from 3.0, 3.3, 4.5 and 10V with a 100% duty cycle (always on), 50% duty cycle or 25% duty cycle. The measurements are being taken with no airflow over the module and an ambient temperature of 22C.

4.5V is the typical drive voltage for 5V logic. By the same token 3V is the typical drive voltage for 3.3V logic. 10V is where the device achieves its minimum Rds(on) and therefore has the lowest possible power dissipation. Our testing on the low end using 3V and 3.3V was better than expected, but devices can vary so use caution if using a drive signal under 4.5V.

In general, you should keep the MOSFETs under about 100°C to keep them happy. For long-term use, 80°C would be a better target.

| Load Amps | 3V 100% | 3V 50% | 3.3V 100% | 3.3V 50% | 3.3V 25% | 4.5V 100% | 4.5V 50% | 4.5V 25% | 10V 100% |

| 5A | 38°C | 34°C | |||||||

| 10A | 82°C | 57°C | 69°C | 49°C | 42°C | 58°C | 52°C | ||

| 15A | X | 96°C | 130+ | 82°C | 54°C | 101°C | 66°C | 83°C | |

| 20A | X | X | X | X | 78°C | 140°C+ | 95°C | 131°C | |

| 25A | X | X | X | X | 100°C | X | 125°C | 76°C | X |

BEFORE THEY ARE SHIPPED, THESE MODULES ARE:

- Sample tested per incoming shipment

Notes:

- The bag usually has a 1×4 male header strip included.

Technical Specifications

Dual Gate Mosfet

| Maximum Ratings | AOD4184 Device Specs | |

| VDS | Drain-Source Voltage | 40V |

| ID | Drain Current Max (Continuous) | 15A (without heat sink) |

| RDS(on) | Drain-Source On-Resistance | 8.5mΩ / 4.25mΩ in parallel (at 4.5V gate) |

| PD | Power Dissipation | 50W (requires heat sink) |

| Dimensions | ||

| (L x W x H) | 34 x 17 x 12mm (1.34 x 0.67 x 0.47″) | |

| Datasheet | AOD4184 |